In today's ultra-competitive environment, engineering needs to be as lean as it is effective. Enabling customers to optimize project performance by delivering engineering solutions using deep resources, comprehensive capabilities and broad industry expertise in a timely, agile and cost-efficient manner.

First we qualified and obtained our AS9100:2016 Rev. D and ISO 9001:2015 certifications while developing, through many years of experience, our own proprietary methodology of engagement and trademarking it as…

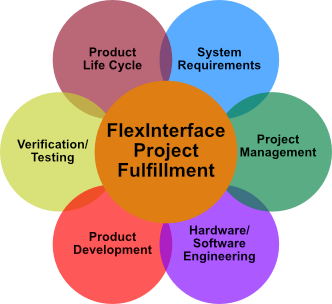

…is our unique methodology that allows us to be strategically and tactically proactive with exceptional agility and rapid deployment. Through our proprietary program management platform, we are able to assess your “program specific” needs at any phase of development, then effectively and efficiently fulfill them with a highly targeted solution. How many times do you allow the true potential gains of outsourcing missed due to your vendors’ dilution of quality engineering; lack of strategic program management, depth of technical resources and overall commitment resulting in missed deadlines, blown budgets and failed projects.

Through our high level of collaborative efforts on many programs since we first started in 2002, we have acquired a strong network of highly experienced and talented suppliers and individuals. The strength of our team has successfully proven itself time and time again in every program we've worked on. These team members can be made available on your next program.

Validated over 30 Airbus ABD documents through multiple revisions to extract ‘shall/will’ requirement statements for flowdown into lower level systems and equipment level requirement documents. This ongoing effort is applicable across all Work Packages.

Populated the DOORS database with flowdown requirements that are linked from the ABD0100 and ABD0200 requirements.

Established and continue to maintain trace links from the DOORS requirements to lower level systems and equipment level documents, providing coverage and traceability for qualification activities.

Updated the requirements tracking database as modified by Airbus ABD document revisions.

Collecting and implementing updated content, holding iterative document reviews and facilitating the approval/release process.

Designing and implementing the requirements compliance tracking system.

Performed lab systems testing for design assurance (all software versions) and for multiple qualification tests (software versions for Airworthiness Authority approval).

Wrote requirements-based test procedures, performed the qualification test and wrote the test reports that cover software versions FCS2, FCS2+, FCS2++,

After certification, developed the Test Plan for intermediate stage testing of software version FCS2+RR (Risk Reduction testing of changes based on in-flight results).

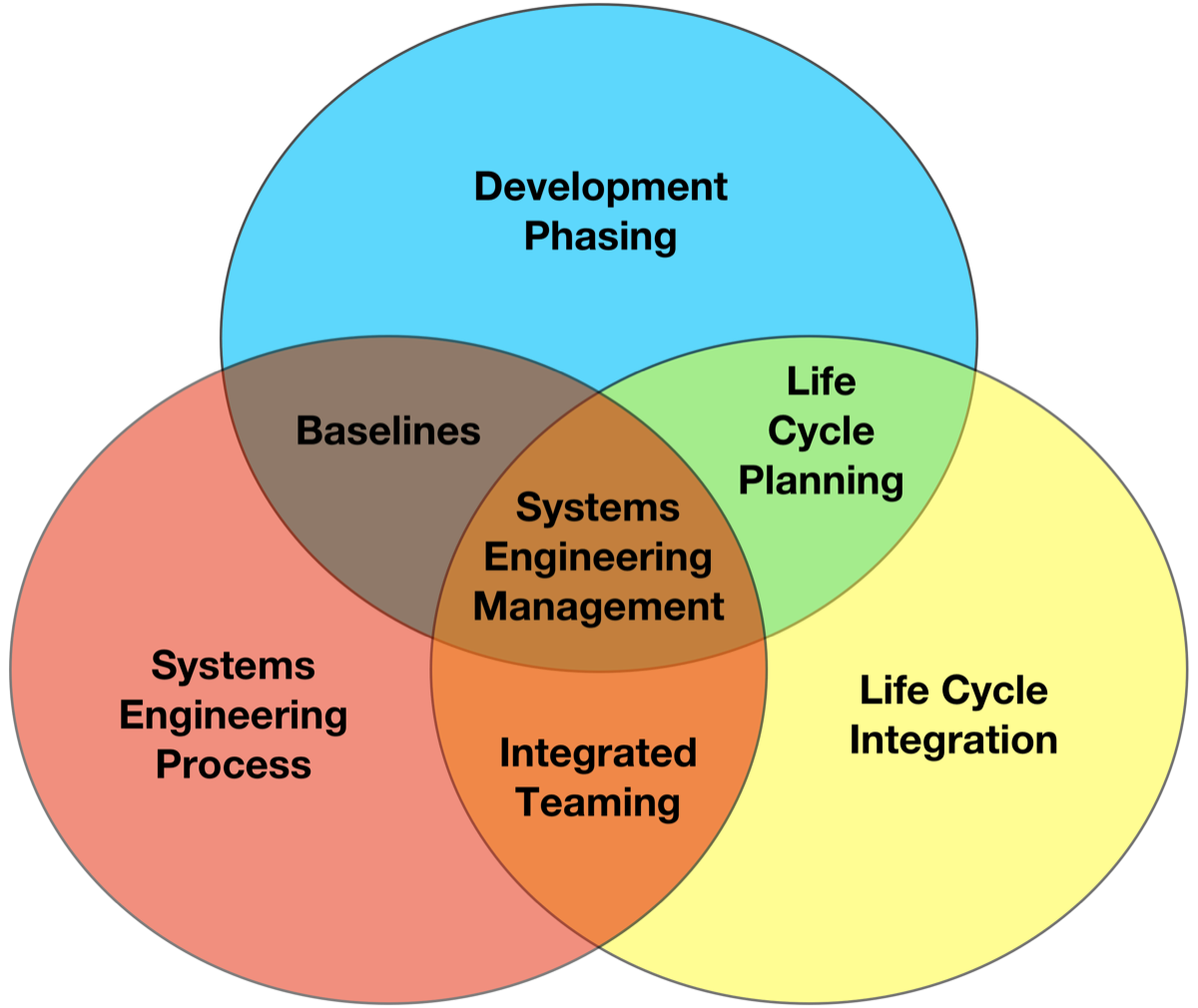

We possess the program management, engineering and technical expertise to support you through every phase of development based on your unique needs and priorities. It’s in our company’s DNA to stay current, provide on-going communication, senior level oversight and to aggressively manage our overhead, providing high-level expertise at very viable costs.

There are some projects that need to be outsourced, others require direct on-site support and then there are some that require both on-site and outsource support. No two projects are identical. Process improvement is critical and having the right teaming partner can make the difference. Each program may require different:

Consolidating your resources and requirements with fewer suppliers is the first step to simplifying your program, project management, quality control and billing. Now add a company with its proprietary process…FlexInterface™Project Fulfillment and the power of our network to further simplify and streamline your processes and program outcomes!

In today's ultra-competitive environment, engineering needs to be as lean as it is effective. Enabling customers to optimize project performance by delivering engineering solutions using deep resources, comprehensive capabilities and broad industry expertise in a timely, agile and cost-efficient manner.

First we qualified and obtained our AS9100:2016 Rev. D and ISO 9001:2015 certifications while developing, through many years of experience, our own proprietary methodology of engagement and trademarking it as…

FlexInterface™Project Fulfillment is our unique methodology that allows us to be strategically and tactically proactive with exceptional agility and rapid deployment. Through our proprietary program management platform, we are able to assess your “program specific” needs at any phase of development, then effectively and efficiently fulfill them with a highly targeted solution. How many times do you allow the true potential gains of outsourcing missed due to your vendors’ dilution of quality engineering; lack of strategic program management, depth of technical resources and overall commitment resulting in missed deadlines, blown budgets and failed projects.

Through our high level of collaborative efforts on many programs since we first started in 2002, we have acquired a strong network of highly experienced and talented suppliers and individuals. The strength of our team has successfully proven itself time and time again in every program we've worked on. These team members can be made available on your next program.

Validated over 30 Airbus ABD documents through multiple revisions to extract ‘shall/will’ requirement statements for flow-down into lower level systems and equipment level requirement documents. This ongoing effort is applicable across all Work Packages.

Populated the DOORS database with flow-down requirements that are linked from the ABD0100 and ABD0200 requirements.

Established and continue to maintain trace links from the DOORS requirements to lower level systems and equipment level documents, providing coverage and traceability for qualification activities.

Updated the requirements tracking database as modified by Airbus ABD document revisions.

Collecting and implementing updated content, holding iterative document reviews and facilitating the approval/release process.

Designing and implementing the requirements compliance tracking system.

Performed lab systems testing for design assurance (all software versions) and for multiple qualification tests (software versions for Airworthiness Authority approval).

Wrote requirements-based test procedures, performed the qualification test and wrote the test reports that cover software versions FCS2, FCS2+, FCS2++,

After certification, developed the Test Plan for intermediate stage testing of software version FCS2+RR (Risk Reduction testing of changes based on in-flight results).

We possess the program management, engineering and technical expertise to support you through every phase of development based on your unique needs and priorities. It’s in our company’s DNA to stay current, provide on-going communication, senior level oversight and to aggressively manage our overhead, providing high-level expertise at very viable costs.

There are projects that need to be outsourced, others require direct on-site support and then there are programs that require both on-site and outsource support. No two projects are identical. Process improvement is critical and having the right teaming partner can make the difference. Each program may require different:

Consolidating your resources and requirements with fewer suppliers is the first step to simplifying your program, project management, quality control and billing. Now add a company with its proprietary process…FlexInterface™Project Fulfillment and the power of our network to further simplify and streamline your processes and program outcomes!

28150 N Alma School Pkwy

Ste 103-631

Scottsdale, AZ 85262

United States