Integrity-EDS engineers specialize not only on how to design and manage complex systems over their life cycles, but are experts at using the tools and software required to perform these jobs. Be assured that the only the right engineer with experience and expertise will be used for your program.

Integrity's team provides a broad range of experience and expertise to both commercial and government aerospace. As a company we have been providing solutions and support to our customers since 2002 while our employees depth of knowledge and experience spans over an average of 24 years. This combined talent assures our customers complete confidence and satisfaction.

We provide experienced Systems Engineers for mechanical, electro-mechanical, electronic and software, test and certification from systems to the component level using requirements-based engineering methodologies (RBE).

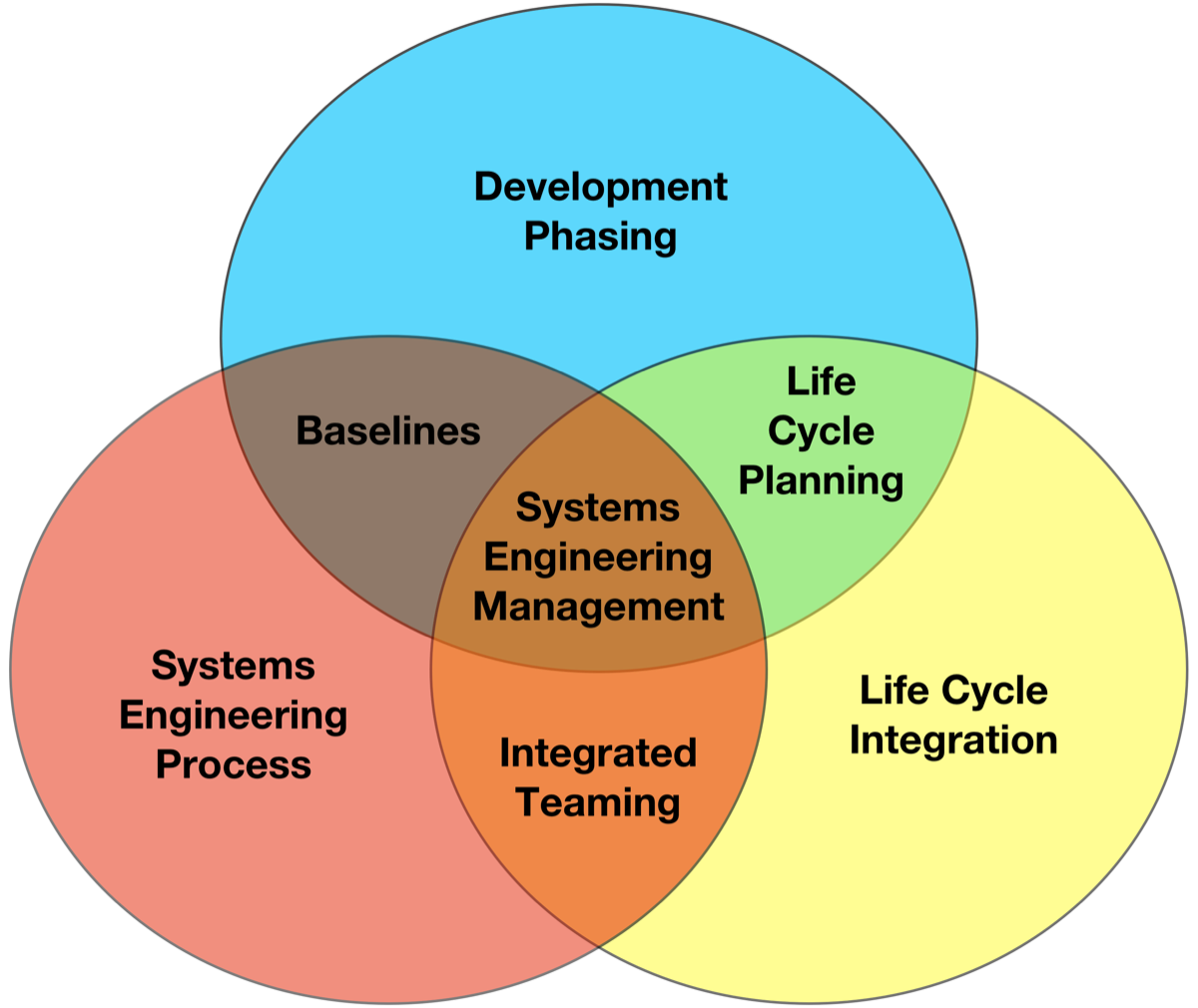

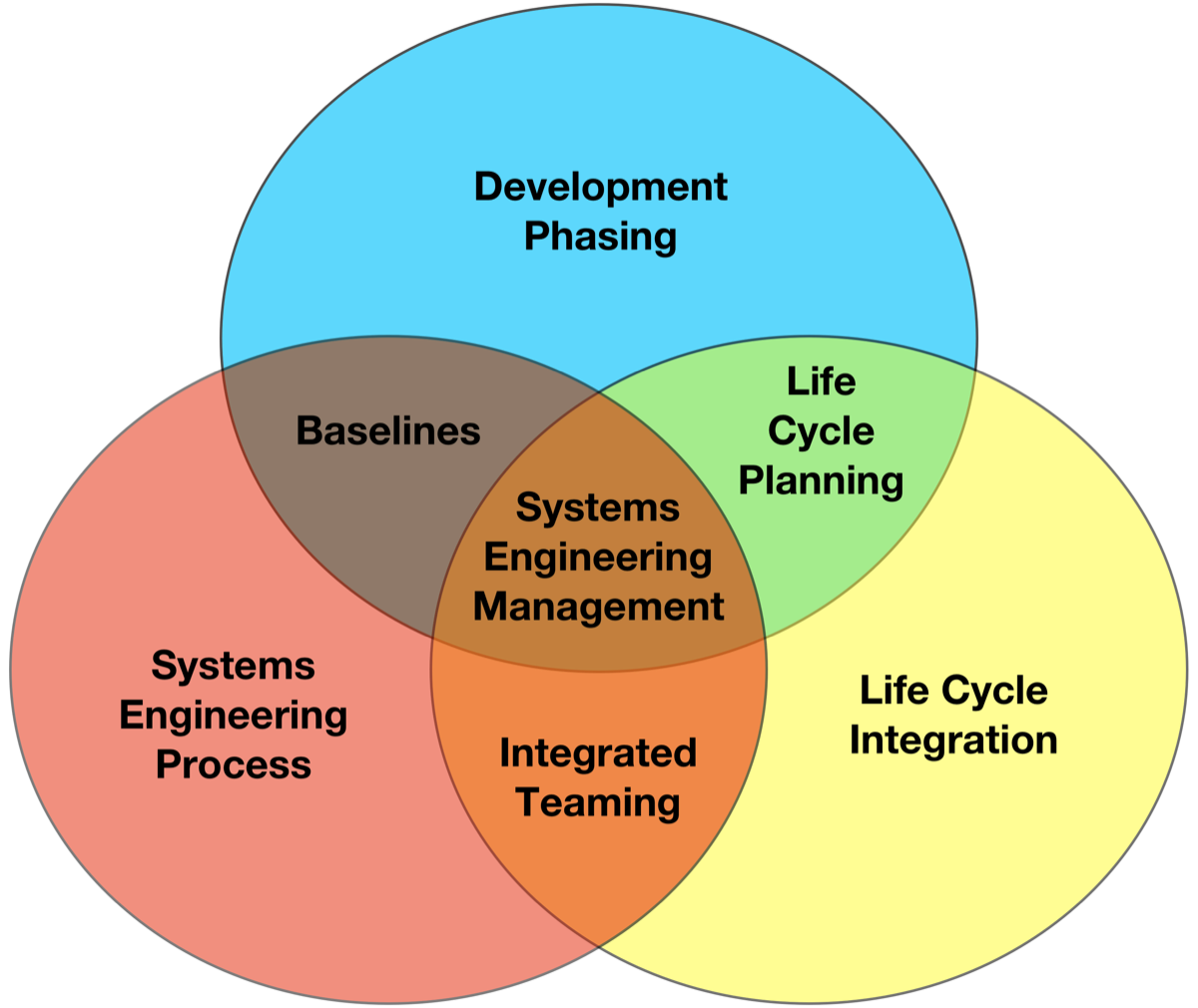

Through our FlexInterface™️ Project Fulfillment processes, we provide a structured yet flexible process that transforms requirements into specifications, architectures, and configuration baselines. Through our ISO 9001:2015 and AS9100:2016 Rev. D 3rd party certified processes, we provide the control and traceability to develop solutions that meet our customers needs.

We ensure that our total system design solutions balances cost, schedule, performance and risk. All technical information is developed and tracked to expedite decision making. We provide a system that can be produced economically and supported throughout the life cycle.

Software and hardware test and certification of the system down to the component level

System life cycle process

Requirements development, management, SEMP utilizing DOORS and Rational Tool Set (ReqPro)

CONOPS development, Customer CONOPS, ORD, TRD analysis

Design Reviews, Audits.

Systems Architecture, DODAF and UML modeling.

Metric development and management.

Systems FMEA, Systems Analysis, Simulation/Modeling, Verification.

Technical Writing.

Statistical analysis

Our hardware team has experience in aerospace, aviation, video, RF, specialized test equipment (STE) and many other applications. We have teamed with major customers in Internal Research and Development (IRAD) projects, supporting them throughout various stages of hardware development. Below are the services that we provide for systems and sub-systems.

Many electrical and mechanical products, both commercially and with the Department of Defense, have exceeded their planned lifecycle, some by decades. This poses a tremendous challenge and threat to the users of this equipment.

Integrity-EDS engineers specialize not only on how to design and manage complex systems over their life cycles, but are experts at using the tools and software required to perform these jobs. Be assured that the only the right engineer with experience and expertise will be used for your program.

Integrity's team provides a broad range of experience and expertise to both commercial and government aerospace. As a company we have been providing solutions and support to our customers since 2002 while our employees depth of knowledge and experience spans over an average of 24 years. This combined talent assures our customers complete confidence and satisfaction.

We provide experienced Systems Engineers for mechanical, electro-mechanical, electronic and software, test and certification from systems to the component level using requirements-based engineering methodologies (RBE).

Through our FlexInterface™️ Project Fulfillment processes, we provide a structured yet flexible process that transforms requirements into specifications, architectures, and configuration baselines. Through our ISO 9001:2015 and AS9100 Rev D certified processes we provide the control and traceability to develop solutions that meet our customers needs.

We ensure that our total system design solutions balances cost, the schedule, performance and risk. All technical information is developed and tracked to expedite decision making. We provide a system that can be produced economically and supported throughout the life cycle.

Software and hardware test and certification of the system down to the component level

System life cycle process

Requirements development, management, SEMP utilizing DOORS and Rational Tool Set (ReqPro)

CONOPS development, Customer CONOPS, ORD, TRD analysis

Design Reviews, Audits.

Systems Architecture, DODAF and UML modeling.

Metric development and management.

Systems FMEA, Systems Analysis, Simulation/Modeling, Verification.

Technical Writing.

Statistical analysis

Our hardware team has experience in aerospace, aviation, video, RF, specialized test equipment (STE) and many other applications. We have teamed with major customers in Internal Research and Development (IRAD) projects, supporting them throughout various stages of hardware development. Below are the services that we provide for systems and sub-systems.

Many electrical and mechanical products, both commercially and with the Department of Defense, have exceeded their planned lifecycle, some by decades. This poses a tremendous challenge and threat to the users of this equipment.

28150 N Alma School Pkwy

Ste 103-631

Scottsdale, AZ 85262

United States